Our Experiments

Our project focus was based on automated self-folding of a polymer sheet by thermal and light activation to explore the ability to convert a two-dimensional polymer into a three-dimensional structure. We achieved this by layering paperboard around the ‘Shrinky-Dink’ polystyrene sheet. The theory behind this is that when a polystyrene sheet is heated to a critical temperature, it shrinks isotopically making it thicker and harder. When the conditions for self-folding are met, the net is able to start folding. The specific regions targeted for folding are in the form of a gap width in the paperboard.

Conventional Oven

This method of self-folding involved heat distribution from a conventional oven, which would thermally activate the polystyrene sheet to start folding into a three dimensional structure. A threshold temperature of 100 degrees was required to initiate folding. Upon reaching temperatures above 120 degrees the sheet stops shrinking and eventually begins to melt.

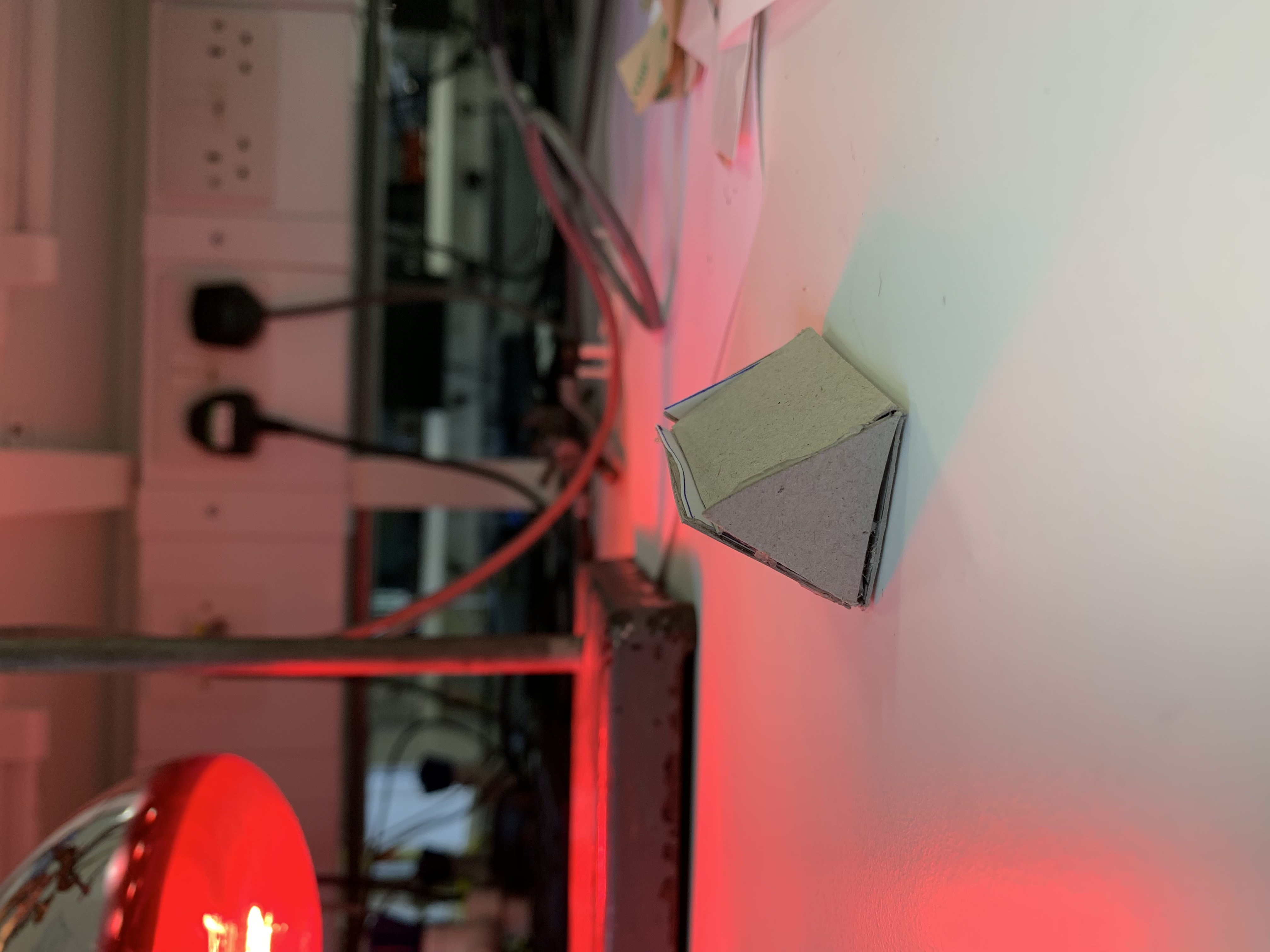

Infra-Red Lamp

This method of self-folding uses an IR bulb to fold predefined ink regions in the gap regions of a polymer sheet net. These regions act as hinges that can fold under light exposure, black ink is most effective since it is most strongly coupled to the electromagnetic field. This allows to rapid contraction of the polymer at the predefined ink regions.

Comparison

When comparing the two methods of creating self-folding objects, the two main obstacles were asymmetry in flat shape preparation and uneven heat distribution. There were also some differences: the IR bulb proved to be a quicker method in folding the 3-D polymers than the oven, partly due to the greater heat absorption at the black hinges. On the other hand, the conventional oven maintained a slightly better temperature distribution, leading to more symmetrically folded shapes.